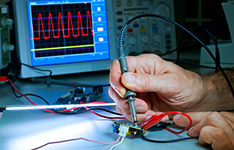

Why Does the Ripple Noise Fail to Meet the Specification?

In the world of electronics, ripple noise is a critical parameter that can significantly affect the performance and reliability of power supplies. When ripple noise fails to meet the specified limits, it can lead to a host of issues, ranging from minor performance degradation to complete system failure. This article delves into the reasons why ripple noise might not meet the specification and provides insights into how to address these issues.

Understanding Ripple Noise and Its Importance

What is Ripple Noise?

Ripple noise refers to the small, periodic fluctuations in the output voltage of a power supply. These fluctuations can be caused by various factors, including imperfections in the power supply circuit, variations in the input voltage, and load changes.

Why is Ripple Noise Important?

Ripple noise is important because it can affect the accuracy and stability of the output voltage. High ripple noise can cause interference in sensitive circuits, leading to errors in data processing and signal transmission. In extreme cases, it can even damage the electronic components.

Common Reasons for Ripple Noise Exceeding Specification

1. Inadequate Filtering

The Role of Filtering in Reducing Ripple Noise

Filtering is a crucial step in reducing ripple noise. It involves using capacitors, inductors, and other components to smooth out the output voltage and remove any unwanted fluctuations.

Why Inadequate Filtering Can Cause Issues

If the filtering components are not properly sized or configured, they may fail to effectively reduce the ripple noise. This can result in the output voltage exceeding the specified limits.

2. Poor Power Supply Design

Design Considerations for Minimizing Ripple Noise

The design of the power supply plays a significant role in determining the level of ripple noise. Factors such as the choice of components, the layout of the circuit, and the regulation method can all affect the ripple noise performance.

Common Design Flaws That Lead to High Ripple Noise

Poor component selection, inadequate circuit layout, and insufficient regulation can all contribute to high ripple noise. These design flaws need to be addressed to ensure that the power supply meets the specification.

3. External Factors

How External Factors Can Affect Ripple Noise

External factors, such as variations in the input voltage, load changes, and electromagnetic interference, can also affect the ripple noise performance of a power supply.

Mitigating the Impact of External Factors

To mitigate the impact of external factors, it is important to design the power supply with robust regulation and filtering mechanisms. Additionally, shielding and grounding techniques can be used to reduce the susceptibility of the power supply to electromagnetic interference.

Addressing Ripple Noise Issues

Steps to Take When Ripple Noise Exceeds Specification

If ripple noise exceeds the specification, the following steps can be taken to address the issue:

- Review the power supply design: Check for any design flaws or inadequacies that may be causing the high ripple noise.

- Upgrade the filtering components: Replace the existing filtering components with higher-quality or better-suited ones to improve the ripple noise performance.

- Implement additional regulation: Add additional regulation stages to the power supply to further reduce the ripple noise.

- Test and validate the power supply: Perform thorough testing and validation to ensure that the power supply meets the specification and performs as expected.

Conclusion: Ensuring Compliance with Ripple Noise Specifications

Ripple noise is a critical parameter that needs to be carefully controlled in power supplies. By understanding the common reasons why ripple noise may exceed the specification and taking the necessary steps to address these issues, it is possible to ensure that the power supply meets the required performance standards. This will not only improve the reliability and performance of the electronic system but also extend the lifespan of the components and reduce the risk of failure.