As the demand for high-performance batteries increases, engineers and researchers continually seek innovative materials to enhance the efficiency and longevity of ternary lithium batteries. CNS ENERGY, a leading Chinese manufacturer of ternary lithium batteries, is at the forefront of this technological evolution. This comprehensive guide delves into the latest advancements in cathode and anode materials, focusing on Nickel Cobalt Manganese Oxide (NCM) and graphite, highlighting the benefits and challenges associated with these materials.

Introduction to Ternary Lithium Batteries

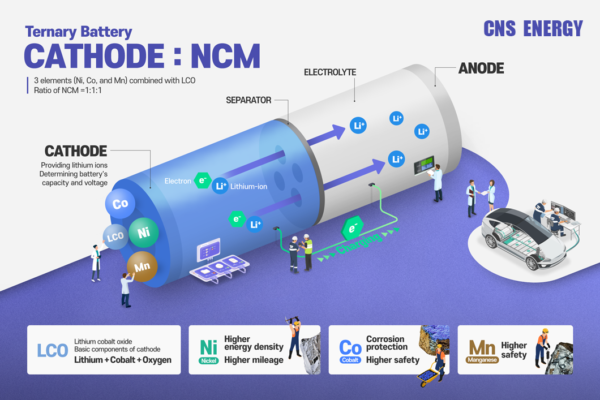

Ternary lithium batteries, also known as NCM batteries, combine nickel, cobalt, and manganese in the cathode. These batteries are renowned for their high energy density, long cycle life, and excellent thermal stability. The anode, typically composed of graphite, complements the cathode to deliver superior performance. This combination makes ternary lithium batteries ideal for applications ranging from electric vehicles to portable electronics.

Nickel Cobalt Manganese Oxide (NCM) Cathodes

Nickel Cobalt Manganese Oxide (NCM) is a pivotal component of modern lithium batteries. The specific formulation of NCM can vary, but it generally consists of nickel, cobalt, and manganese in different ratios, such as NCM 111 (equal parts of each element), NCM 523, and NCM 811.

Benefits of NCM Cathodes

High Energy Density: NCM cathodes provide a high energy density, which translates to longer battery life and extended usage between charges. This is crucial for applications like electric vehicles (EVs), where range anxiety is a significant concern.

Thermal Stability: NCM materials offer excellent thermal stability, reducing the risk of overheating and thermal runaway. This makes them safer for high-power applications.

Scalability: The use of NCM cathodes is scalable for mass production, making them cost-effective for large-scale applications.

Challenges of NCM Cathodes

Resource Availability: The sourcing of nickel and cobalt is subject to geopolitical and environmental constraints. The mining of these elements can have significant environmental impacts, leading to increased scrutiny and regulation.

Cost: While prices have stabilized, the cost of cobalt, in particular, remains high, influencing the overall cost of NCM batteries.

Cycle Life: Despite improvements, NCM batteries can suffer from capacity fade over time, especially under high charge/discharge rates.

Graphite Anodes

Graphite remains the anode material of choice for most lithium-ion batteries, including NCM batteries. Its ability to form a stable, reversible lithium-ion intercalation compound makes it ideal for this application.

Benefits of Graphite Anodes

High Electrical Conductivity: Graphite’s excellent electrical conductivity ensures efficient charge and discharge cycles, enhancing overall battery performance.

Stable SEI Formation: The solid electrolyte interface (SEI) formed on graphite anodes is stable, contributing to the battery’s longevity and safety.

Abundant Supply: Graphite is relatively abundant and less costly compared to other advanced anode materials, making it an economically viable option.

Challenges of Graphite Anodes

Capacity Limitation: Graphite anodes have a theoretical capacity limit of 372 mAh/g, which can be a constraint for applications requiring ultra-high energy density.

Lithium Plating: At high charge rates, lithium can plate on the graphite surface, leading to reduced capacity and potential safety issues.

Mechanical Degradation: The repeated intercalation and deintercalation of lithium ions can cause mechanical degradation of the graphite structure over many cycles, affecting the battery’s lifespan.

Future Directions and Innovations

To address the challenges associated with NCM cathodes and graphite anodes, researchers are exploring several innovative approaches:

Cobalt-Free Cathodes: Reducing or eliminating cobalt from the cathode composition can mitigate resource and cost concerns. Alternatives like Nickel-Rich and Lithium Iron Phosphate (LFP) are being actively researched.

**Silicon

Enhanced Anodes: Silicon anodes, either standalone or as silicon-graphite composites, offer significantly higher theoretical capacities (up to 4200 mAh/g). Integrating silicon can potentially increase the overall energy density of the battery.

Solid-State Electrolytes: Transitioning to solid-state electrolytes can improve safety by eliminating flammable liquid electrolytes and increasing energy density by allowing for thinner, more compact designs.

Advanced Coatings: Developing advanced coatings for NCM cathodes and graphite anodes can enhance their stability, reduce degradation, and improve cycle life. Coatings such as Al2O3 or ZrO2 can provide additional protection against electrolyte interactions.

Practical Applications and Considerations

Electric Vehicles (EVs)

The automotive industry is a major consumer of ternary lithium batteries. The high energy density of NCM cathodes and the stability of graphite anodes make them ideal for EVs, providing longer driving ranges and better performance. Companies like Tesla and Nissan are actively incorporating NCM-based batteries into their latest models.

Fast Charging: Enhancing the charging speed without compromising battery life or safety is crucial for consumer convenience.

Safety: Ensuring thermal stability and robust safety mechanisms is essential to prevent battery failures.

Portable Electronics

Ternary lithium batteries are widely used in smartphones, laptops, and other portable electronics due to their compact size and high energy output. The balance of energy density and safety provided by NCM and graphite materials is particularly beneficial in these applications.

Key Considerations:

Battery Life: Consumers demand long-lasting batteries that can support high-performance features without frequent recharging.

Form Factor: The battery’s size and shape must be adaptable to the sleek designs of modern electronics.

Reliability: Consistent performance over hundreds of charge cycles is critical for consumer satisfaction.

Renewable Energy Storage

For grid-scale energy storage solutions, ternary lithium batteries offer a reliable option. Their high energy density and scalability make them suitable for storing renewable energy generated by solar and wind power systems.

Conclusion

CNS ENERGY’s commitment to advancing ternary lithium battery technology is evident in the continuous improvements in NCM cathodes and graphite anodes. By addressing the benefits and challenges of these materials, CNS ENERGY not only enhances battery performance but also contributes to the broader adoption of electric vehicles, portable electronics, and renewable energy solutions.

For engineers and researchers, staying abreast of these advancements is crucial. The future of battery technology lies in innovative materials and designs that push the boundaries of energy density, safety, and longevity.