Lithium iron phosphate battery, as a high performance and long-life lithium-ion battery, is widely used in electric vehicles, energy storage systems, portable equipment and other fields. In this paper, we will deeply discuss the discharge principle of Lithium iron phosphate battery and reveal the key factors of its excellent performance and reliability.

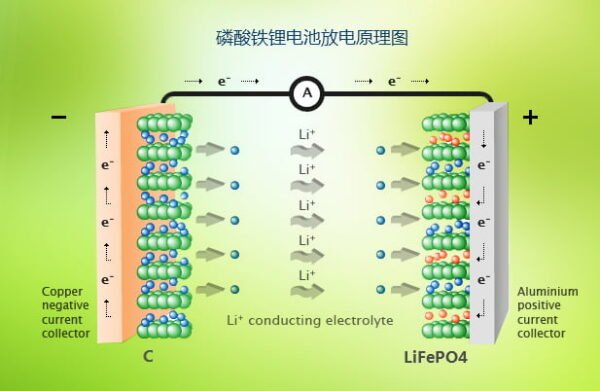

The discharge process of Lithium iron phosphate battery involves ion migration and electrochemical reaction between Lithium iron phosphate cathode material, graphite cathode material and electrolyte. In the discharge process, lithium ions are disembedded from the cathode material and migrated to the cathode material through the Ion channel in the electrolyte. At the same time, electrons flow from the positive electrode material through an external circuit to the negative electrode material, generating electrical energy.

Lithium iron phosphate cathode material is one of the key factors of battery performance. The cathode material is usually composed of Lithium iron phosphate crystal and conductive agent. In the discharge process, lithium ions are disembedded from the Lithium iron phosphate cathode material and electrochemical reaction occurs with the carbon material on the cathode material. This electrochemical reaction promotes the migration of lithium ions in the battery, resulting in the generation of electrical energy. The cycle life and power performance of the battery are determined by the structural stability and electrochemical performance of Lithium iron phosphate material.

Graphite anode material is a key component of Lithium iron phosphate battery. During the discharge process, lithium ions detach from the positive electrode material and migrate to the graphite negative electrode material. This process is called intercalation/delamination reaction. The intercalation and delamination processes of lithium ions have a significant impact on the capacity and power density of batteries. High quality graphite materials can provide higher lithium intercalation/de intercalation capabilities, and can quickly and stably intercalate and de intercalate lithium ions, thereby improving the performance and lifespan of batteries.

Electrolyte plays a key role in ion conduction in Lithium iron phosphate battery. The common electrolyte is organic solution, which can provide Ion channel and promote the migration of lithium ions between the positive and negative poles. A high-quality electrolyte should have good ion conductivity, chemical stability, and high-temperature resistance to ensure the reliability and safety of the battery.

CNS has been committed to the research and innovation of Lithium iron phosphate battery technology. By deeply understanding the discharge principle of Lithium iron phosphate battery, we can provide high-performance and long-life battery solutions to meet customers’ growing energy needs.

If you have more questions about the discharge principle of Lithium iron phosphate battery or want to know more details, please visit our website or contact our team. We will be very happy to share our professional knowledge with you and provide you with personalized solutions.