With the continuous development of battery technology, batteries, as the core components of energy storage, are more and more widely used in various fields. However, quality control during battery production has been a key factor restricting its reliability and performance. In order to improve the quality and reliability of batteries, CNS has summarized some key methods and implementation strategies in years of research and practice, and now I would like to share them with you as follows:

Strict raw material selection and supply chain management:

High-quality raw materials are the basis for ensuring battery quality. Establish a reliable supply chain and strictly screen raw material suppliers to ensure the stability and consistency of raw materials. Raw materials are thoroughly tested and verified to ensure compliance with product requirements and international standards.

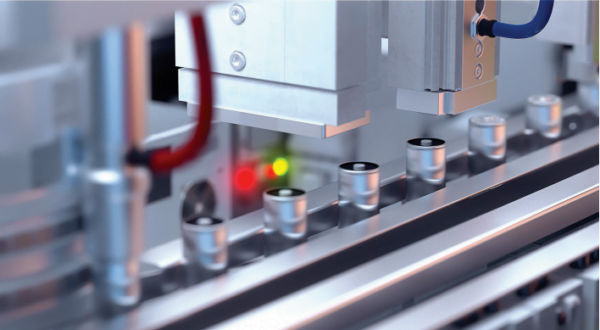

Strengthen production process control:

Establish a complete production process and quality control process, and strictly monitor every aspect of battery manufacturing. Introduce advanced automation equipment and testing technology to ensure the accuracy and consistency of the production process. Implement strict quality inspection and product sampling test to ensure the compliance and stability of each batch of batteries.

Continuous improvement and data analysis:

Establish a quality management system, collect and analyze key data in the production process. Through data analysis, potential problems and improvement opportunities can be discovered in time. Implement continuous improvement measures to optimize production process and control parameters to improve battery quality and performance.

Training and Upskilling:

A comprehensive training and upskilling program is provided for production personnel to ensure they have good process understanding and operational skills. Cultivate employees’ quality awareness and sense of responsibility, so that they can actively participate in the process of quality control and improvement.

Establish a sound quality assurance system:

Establish a strict quality assurance system, including quality management manuals, document records and internal audit procedures. Ensure that every step of operation complies with standards and specifications, and implement strict quality management and quality tracking.

CNS is committed to the research and development and production of battery technology, we know the importance of quality for the battery industry. Through the above key methods and implementation strategies, we have successfully improved the production quality and stability of batteries, and provided customers with more reliable and high-performance energy solutions.

As an industry leader, we will continue to devote ourselves to quality control and technological innovation, and continuously improve the quality and performance of batteries to meet the growing needs of customers.

If you have further needs or want to know more details about battery production quality control, please visit our website or contact our team. We will be more than happy to share our experience and knowledge with you and provide you with professional solutions.

Thank you for your attention and support to CNS. We look forward to working with you to promote the development of the battery industry and create more reliable and high-quality battery products together.