As an advanced battery technology widely used in mobile devices, electric vehicles, and renewable energy storage, understanding the discharge principle of lithium polymer batteries is crucial for the performance and reliability of batteries. In this article, we will delve into the discharge principle of lithium polymer batteries, showcasing their technical core and reliability assurance.

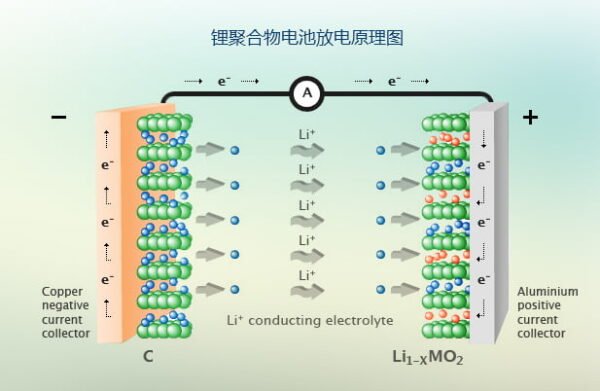

The discharge process of lithium polymer batteries mainly involves the migration of lithium ions between positive and negative electrodes and electrochemical reactions. In the discharge process, the lithium ion in the positive material (usually composed of lithium Transition metal oxides) migrates to the negative material (usually composed of graphite or Graphene) and conducts through the Ion channel in the electrolyte. This migration process generates electron flow, which in turn generates electrical energy.

In lithium polymer batteries, the electrolyte is usually a polymer matrix, such as polymer gel or polymer film. The main advantages of polymer electrolytes lie in their high ionic conductivity and good chemical stability, allowing for rapid and reliable migration of lithium ions in batteries. In addition, polymer electrolytes also have high mechanical flexibility, which can adapt to the deformation and deflection of the battery, improving the safety of the battery.

Another key factor is the reaction characteristics of positive and negative electrode materials. The cathode material is usually composed of lithium Transition metal oxides, such as lithium cobalate or lithium manganate. During the discharge process, lithium ions in the positive electrode material release electrons and undergo chemical reactions with carbon materials (such as graphite) in the negative electrode material. This electrochemical reaction allows lithium ions to migrate in the battery, generating electrical energy.

In order to ensure the reliability and safety of lithium polymer batteries, strict control of the battery structure and components is required during the design and manufacturing process. For example, the separator material of a battery needs to have good ion transfer performance and thermal stability to prevent ion short circuits and overheating inside the battery. In addition, the battery also needs a reasonable Battery management system (BMS) to monitor the battery status, temperature, current and other parameters to ensure the normal operation and safety of the battery.

At CNS, we are committed to the research and innovation of lithium polymer battery technology. By deeply understanding the discharge principle of lithium polymer batteries, we can provide high-performance and reliable battery solutions to meet customers’ growing energy needs.

If you have more questions about the discharge principle of lithium polymer batteries or would like to learn more details, please visit our website or contact our team. We will be very happy to share our professional knowledge with you and provide you with personalized solutions.